Torches

Home » Why choose Miller® | Smith Equipment® » Torches

Torch Handles

Our torch handles are 100-percent tested and inspected. They are available in three capacities to match any job requirement: heavy-duty, medium-duty and standard-duty.

Torches have silver-brazed joints to provide overall strength and rigidity for safe performance under rugged conditions.

Torch handles are individually tested to maintain our reputation for quality and dependable performance.

Construction Features

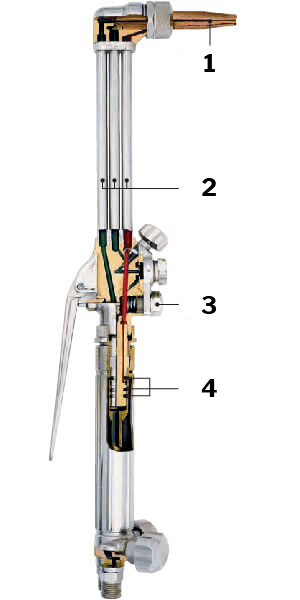

These torches have five key features, which are:

1) Internal threads

Threads are protected from damage if the torch is dropped, eliminating costly torch repair, replacement or downtime.

2) Double-tube handle

Tube-within-a-tube design provides strength while reducing weight. Internal tube is silver brazed for extra protection, strength and leak resistance.

3) Adjustable valve resistance

Special PTFE packing provides a gas-tight seal while allowing the “drag” to be adjusted to the individual preference.

4) Stainless steel ball-style valves

Corrosion-resistant balls and brass seating surfaces provide gall resistance and positive, chatter-free seating.

5) Replaceable hose connections (WH200A)

Connections are easily replaced if damaged on the heavy-duty WH200A handle.

Image: 1) Internal threads 2) Double tube handle 3) Adjustable valve resistance 4) Stainless steel ball-style valves 5) Replaceable hose connections (WH200A) 6) Tube-in-tube construction 7) Fuel 8) Oxygen.

Cutting Attachments

Our premium-quality cutting attachments are 100-percent tested and inspected. They are available in three capacities to match any job requirement: heavy-duty, medium-duty and standard-duty.

Cutting attachments have silver-brazed joints to provide overall strength and rigidity for safe performance under rugged conditions.

Attachments are individually tested to maintain our reputation for quality and dependable performance.

Construction features

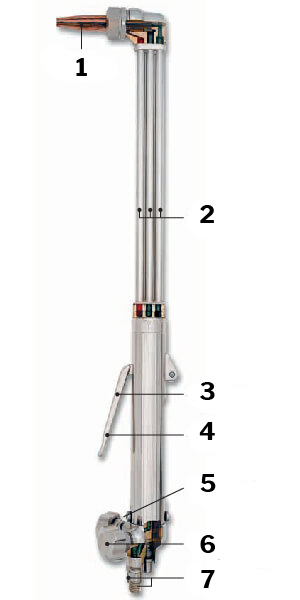

These cutting attachments have four key features, which are:

1) Slip-in cutting tips

Save time when changing tips — no wrench needed. Resilient Graf-Tite® seat material protects tip from nicking and maintains positive seating. Requires less replacement than metal-to-metal seat designs.

2) Three-tube construction

Gases are kept separated, eliminating mixing tube burnout. Our thick-wall, high-capacity stainless steel tubes provide high gas flow and superior strength.

3) Ease-on oxygen cutting valve

Allows smooth piercing and keyhole free starts and restarts.

4) Triple o-ring seal

Provides positive gas seating, and allows rotation during operation eliminating hose resistance during cutting.

Image: 1) Slip-in cutting tips 2) Three tube construction 3) Ease-on oxygen cutting valve 4) Triple o-ring seal.

Hand Cutting Torches

Our hand cutting torches are of heavy-duty capacity, and 100-percent tested and inspected.

Cutting torches feature solid construction and ease of operation for hundreds of jobs in construction, fabricating, shipyards, salvage and other related industries.

Torches have silver-brazed joints throughout, heads and butts are machined from dense forgings, and stainless steel ball-style control valves provide positive gas shut-off.

Torches are individually tested to maintain our reputation for quality and dependable performance.

Construction features

These hand cutting torches have seven key features, which are:

1) Slip-in cutting tips

Save time when changing tips — no wrench needed. Resilient Graf-Tite® seat material protects the tip from nicking and maintains positive seating. Requires less replacement than metal-to-metal seat designs.

2) Three-tube construction

Gases are kept separated, eliminating mixing tube burnout. Our thick-wall, high-capacity stainless steel tubes provide high gas flow and superior strength.

3) Ease-on cutting oxygen

Exceptionally smooth application of cutting oxygen reduces keyholing and slag blowback without sacrificing extremely high cutting capacity.

4) Reversible cutting lever

Top- or bottom-mount lever for ease of use.

5) Adjustable valve resistance

Special PTFE packing provides a gas-tight seal while allowing the “drag” to be adjusted to the individual preference.

6) Stainless steel ball-style valves

Provides smooth adjustment and positive seating.

7) Filtered replaceable hose connections

Connections are easily replaced if damaged. Filters keep debris from entering the cutting mechanism and high-pressure seat.

Image: 1) Slip-in cutting tips 2) Three tube construction 3) Ease-on cutting oxygen 4) Reversible cutting level 5) Adjustable valve resistance 6) Stainless steel ball-style valves 7) Filtered replaceable hose connections.

Gas Axe™ Hand Cutting Torches

Our hand cutting torches are of heavy-duty capacity, and 100-percent tested and inspected.

Cutting torches feature solid construction and ease of operation for hundreds of jobs in construction, fabricating, shipyards, salvage and other related industries.

Torches have silver-brazed joints throughout, heads and butts are machined from dense forgings, and stainless steel ball-style control valves provide positive gas shut-off.

Torches are individually tested to maintain our reputation for quality and dependable performance.

Construction features

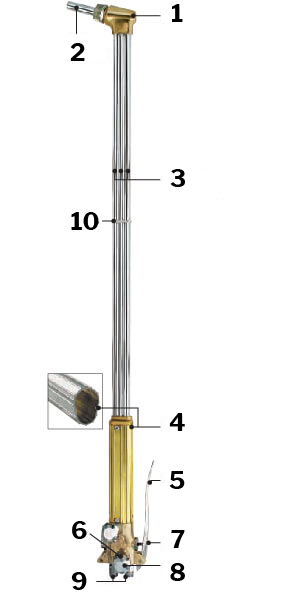

These hand cutting torches have seven key features, which are:

1) Slip-in cutting tips

Save time when changing tips — no wrench needed. Resilient Graf-Tite® seat material protects tip from nicking and maintains positive seating. Requires less replacement than metal-to-metal seat designs.

2) Three-tube construction

Gases are kept separated, eliminating mixing tube burnout. Our thick-wall, high-capacity stainless steel tubes provide high gas flow and superior strength.

3) Ease-on cutting oxygen

Exceptionally smooth application of cutting oxygen reduces keyholing and slag blowback without sacrificing extremely high cutting capacity.

4) Reversible cutting lever

Top- or bottom-mount lever for ease of use.

5) Adjustable valve resistance

Special PTFE packing provides a gas-tight seal while allowing the “drag” to be adjusted to the individual preference.

6) Stainless steel ball-style valves

Provides smooth adjustment and positive seating.

7) Filtered replaceable hose connections

Connections are easily replaced if damaged. Filters keep debris from entering the cutting mechanism and high-pressure seat.

Image: 1) Thick-wall forged brass head 2) Slip-in cutting tips 3) Three-tube construction 4) Ergonomic handle 5) Reversible cutting lever 6) Adjustable valve resistance 7) Ease-on cutting oxygen 8) Stainless steel ball-style valves 9) Replaceable hose connections 10) Tube supports.

This is the oxy-fuel equipment with the world's safest design and reliability

Miller® | Smith Equipment® has always been designed with safety in mind. You can be sure of the reliability of these equipment throughout the years. Take a further look at some of its other main features.

Our tips are 100-percent tested and inspected and are the longest lasting tips you can buy…

Miller® | Smith Equipment® has heavy and medium duty as well as single, two and three stages regulators, among others…

What's next?

Choose your next action among these.