Heating, Cutting & Welding Tips

Home » Why choose Miller® | Smith Equipment® » Heating, Cutting & Welding Tips

Cutting Tips

Our tips are 100-percent tested and inspected and are the longest lasting tips you can buy.

Whatever your application, whatever your fuel gas, we have a tip that provides fast, economical and quality cutting.

Select the tip to match the job. It’s faster, gives a cleaner cut, cuts expensive labor time, and saves on cleanup, machining and gas.

Select from quality tips for dependable performance with acetylene, natural gas (city gas), propane and propylene-based fuels.

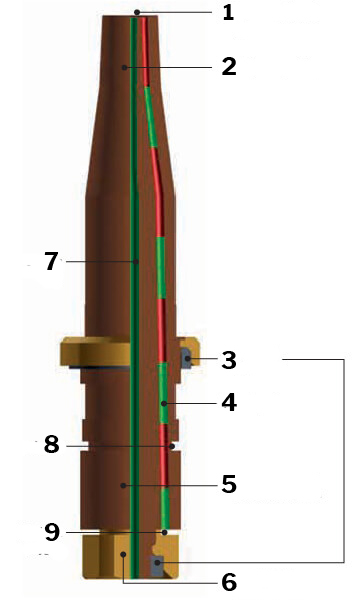

Construction features

These cutting tips have six key features, which are:

1) Concave-shaped tip end

Reduces backfire and resists flameout when making accidental contact with base metal during cutting operations.

2) Fully swaged tip

Mirror-smooth gas passages minimize turbulence to deliver stable gas flows for fast starts and precision cuts. Also minimizes slag build-up and reduces clean-up time.

3) Graf-Tite® soft seats

Resilient Graf-Tite® seat material protects tip seating areas from nicking to maintain positive seating. Requires less replacement than metal-to-metal seat designs.

Compressible soft seats are practically indestructible and withstand extremely high temperatures, resulting in longer tip life.

4) In-tip mix

Each tip is a precision engineered mixer for combining preheated oxygen and fuel gas to attain maximum efficiency. Adds resistance to flashback.

5) Slip-in tip design — just hand tighten

After the first tightening with a wrench, only hand tightening is required to seat the tip, saving time when changing tips. Quick and easy tip changes encourage use of the right tip for the job.

6) Removable high-pressure seat

Allows cleaning from the back of the tip.

Image: 1) Concave-shaped tip end 2) Fully swaged tip 3) Graf-Tite®soft seats 4) In-Tip mix 5) Slip-in design -just hang tighten 6) Removable high-pressure seat 7) Oxygen jet 8) Fuel port 9) Preheat oxygen.

Welding Tips

Our “soft flame” welding tips are 100-percent tested and inspected, and make welding easier.

Our welding tips are quality engineered to provide easy handling, high performance and added protection in welding, brazing and soldering operations.

Each tip is individually tested on our automatic testing machines and must pass stringent requirements for flame characteristics, gas flow and resistance to backfire or flashback.

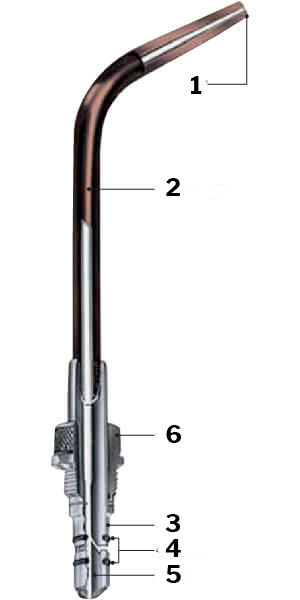

Construction features

These welding tips have four key features, which are:

1) “Soft flame”

Our “soft flame” welding tips provide concentrated heat for better “puddle” control — the turbulent-free flame eliminates puddle chasing.

Soft flame provides deep, even penetration without burning through base metal for strong, dependable welds. Molten metal is protected from atmospheric oxidation by a smooth, even flame envelope.

2) Heavy-wall copper

Heavy-wall copper gives greater resistance to reflected heat, permits cooler operation, and dissipates more heat than thin-wall copper.

Heat-absorbing tips provide longer life, and the long straight-away design permits tip refacing after excessive wear or abuse.

3) Slip-in tips

Tips may be rotated 360 degrees for convenient positioning, eliminating hose resistance during operation. Slip-in tips can be changed in just seconds. Hand tighten, no wrench needed.

O-rings provide gas-tight seal keeping gases separate until they mix in the tip.

4) O-ring seals

O-rings provide a gas-tight seals with no metal seating surface to damage if dropped. Gases are kept separate until entering the mixing chamber.

Image: 1) “Soft flame” 2) Heavy-wall copper 3) Slip-in tips 4) O-ring seals 5) In-tip mix 6) Individual mixers

This is the oxy-fuel equipment with the world's safest design and reliability

Miller® | Smith Equipment® has always been designed with safety in mind. You can be sure of the reliability of these equipment throughout the years. Take a further look at some of its other main features.

Torches have silver-brazed joints to provide overall strength and rigidity for safe performance under rugged conditions…

Miller® | Smith Equipment® has heavy and medium duty as well as single, two and three stages regulators, among others…

What's next?

Choose your next action among these.